The Future of Metal Cutting

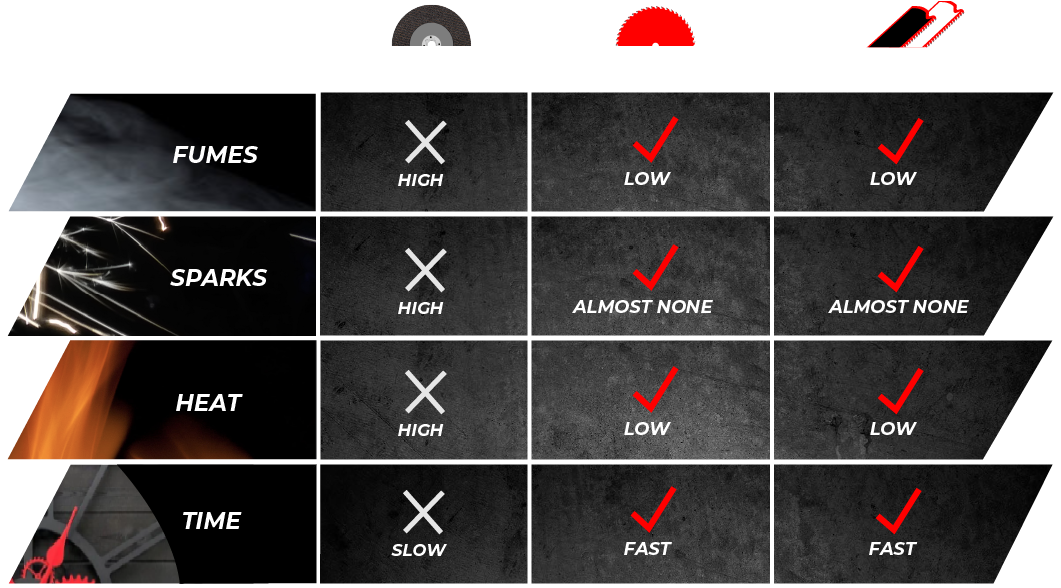

There's a new way to cut metal. A way that results in less sparks, less heat, less fumes, and a superior quality finish saving you time and money.

THE 19TH CENTURY APPROACH

For over 100 years, abrasive discs, also known as bonded discs, cut-off discs or grinding discs, have been one of the primary ways to cut metal on the jobsite.

One big reason for their adoption was the low cost of the discs themselves. However, the overall higher cost of this technique has become clear to professionals as better solutions appeared in the market.

Factors that increase the cost of using abrasive discs include the additional safety precautions that are needed because of the fumes and sparks they produce, the poor quality of cut that often requires extensive rework and the number of labor hours lost in waiting to rework as the piece cools as well as the time it takes to replace disc after disc.

THE FUTURE OF METAL CUTTING

With technology advancements, first with new carbide teeth formulations and now with Cermet (ceramic metallic) teeth, the state-of-the-art for metal cutting applications have shifted away from abrasive discs and decisively towards circular saw blades and reciprocating blades.

Professional’s value their time and their money and, more importantly, they take pride in the quality and productivity of their work. The issues with bonded discs stem from their low-tech approach to the application. They melt through material with a tremendous amount of kinetic energy, far more than is necessary. The problem is there is no way to control and direct that energy with precision. It is like using a sledge-hammer to frame a house.

The advantage of reciprocating blades and circular saw blades is in channeling their energy into the cut with precision. It results in vastly superior and clean cuts and is evidenced in the much lower temperature of the finished work piece.

SOLVING PROBLEMS WITH DIABLO SOLUTIONS

Try Diablo’s Steel DemonTM Saw Blades and Reciprocating Blades

Diablo's Metal Cutting Circular Saw Blades

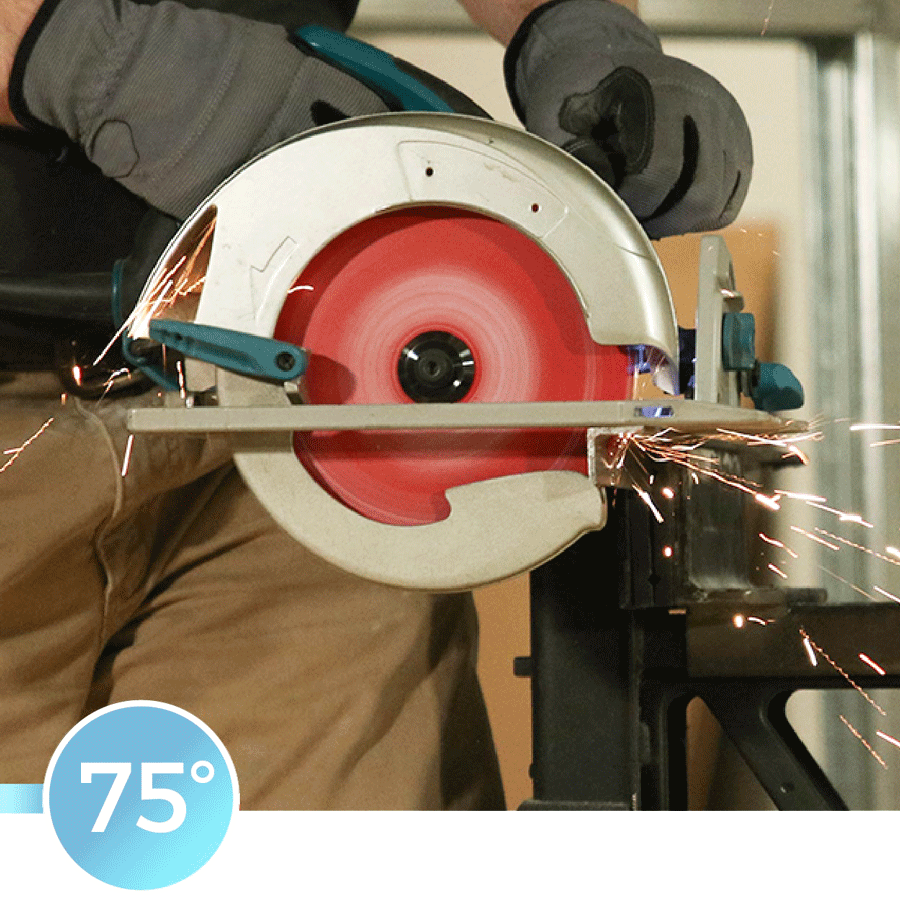

Diablo’s Steel DemonTM saw blades are redefining metal cutting, and the jobsite, by introducing exclusive innovation for cutting metals and stainless steels with a cordless or corded circular saw.

Diablo’s Steel Demon Cermet saw blades feature specially formulated Cermet II teeth that provide high heat tolerance and increased hardness for superior wear and life delivering up to 25X longer life, 50X cooler cuts and 10X faster cuts when compared to standard grinding discs.

Featuring a special Triple Chip Grind and Perma-SHIELD® coating, these blades slice through the toughest of metals to produce precise, burr-free cuts with less sparks. A controlled cutting action produces larger chip sizes that generates less dust and airborne contaminates.

The ability to cut through both metals and stainless steels eliminates the need for individually dedicated saw blades, offering a one-blade solution for the ultimate metal cutting performance and an unmatched value.

Features:

- Cermet II (Ceramic and Metallic) teeth deliver a more efficient and productive metal cutting solution through high heat tolerance and increased hardness for superior wear, fewer blade changes and up to 25X longer life versus standard grinding discs

- Optimized blade design reduces wandering and deflection of metal, creating precise cuts that require virtually no re-work

- Up to 50X cooler cuts with a circular saw blade when compared to a grinding disc that increases temperature of steel by up to 500 degrees. Grinding discs increase the temperature enough to permanently discolor the steel.

- Up to 10X faster cuts with a circular saw blade for maximum productivity and efficiency, resulting in up to 60 seconds faster cuts in both metals and stainless steels versus standard grinding discs

- Circular saw blades create a controlled cutting action resulting in larger chip sizes that generates less dust and airborne contaminates versus standard grinding discs

- Triple Chip Cutting action reduces sparks and the possibility of needing “hot” permits

"This blade is a BEAST! Love the easy cutting with this bad boy."

Handyman - Pro

"Best cutting blade I have ever used. Wouldn’t buy any other brand."

Plumber - Pro

"After using it half the day its still as sharp like when I started."

Maintenance/Repair - Pro

Diablo's Metal Cutting Reciprocating Saw Blades

Diablo’s range of Steel DemonTM reciprocating saw blades are “AMPing Up” metal cutting with the introduction of industry first technology and innovation to make metal cutting more efficient and productive, saving the Pro time and money.

Diablo’s first ever AMPED thick metal reciprocating blade’s featuring the industry’s first ever industrial grade coating, Black Industrial Cooling Element (I.C.E.).The ultra-slick Black I.C.E. provides the coolest and cleanest cutting edge, and an ultra-superior chip evacuation. High performance carbide delivers an unmatched up to 100X longer cutting life in metal cutting applications ranging in thickness from 3/16 in. to 9/16 in. The combination of Black I.C.E. and Diablo’s carbide delivers extended life and an impressive up to 2X increased performance vs. standard metal cutting carbide reciprocating saw blades.

Features:

- Up to 100x longer life in metal cutting applications

- Diablo made TiCo Hi-Density carbide delivers the greatest durability and cutting performance in thick metal applications

- Enhanced carbide tip to blade connection for extreme impact resistance

- Black I.C.E. coating protects carbide cutting edge by creating a slick, lubricant like action for a cool cutting edge and superior chip evacuation

- 1 in. oversized blade body provides stability and rigidity for straighter cuts with less vibration

- Perma-SHIELD® resists heat build-up by protecting the blade against gumming and corrosion

"Amped blades are now going to be the only blades that we use."

Fire & Rescue - Pro

"I was able to cut out cast and iron for an entire waste re-pipe with one blade!"

Plumber - Pro

"This blade really does the job and makes light work of thick metals!"

Automotive - Pro

DIABLO'S FULL LINE TO REDEFINE METAL CUTTING

Diablo offers a full range of premium solutions for metal cutting applications. From metal cutting circular saw blades to fit a large variety of tools from 5-3/8" to 14" to reciprocating blades for thin, thin conduit, medium, and thick metal applications.